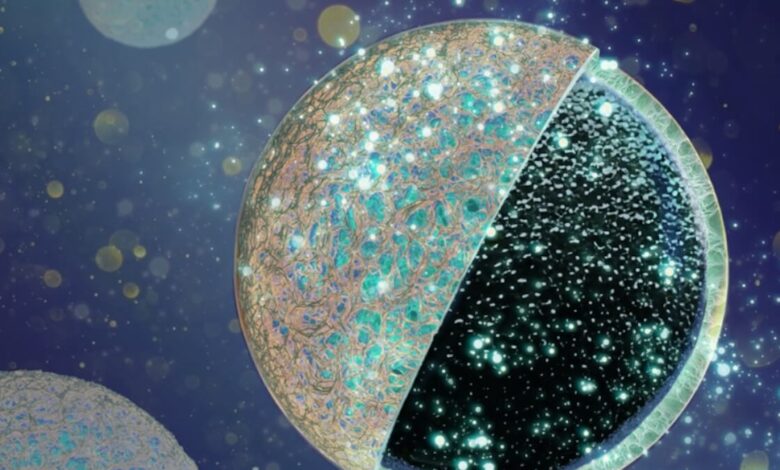

Researchers at the Federal Institute for Materials Research and Testing have developed a novel core-shell design for sodium-ion batteries. This will allow the previously low efficiency of the technology to be massively increased and could represent an important step towards more sustainable and cost-effective energy storage.

Whether in smartphones, laptops or electric cars – lithium-ion batteries dominate the battery market worldwide. In addition, with the increasing electrification of mobility and energy supply, the demand for powerful energy storage is increasing.

It is estimated that global demand for lithium-ion batteries will increase to 4.2 terawatt hours by 2030. For comparison: in 2021 it was still 235 gigawatt hours. That would correspond to an increase of around 18-fold within less than ten years.

Their high energy density and long service life make lithium-ion batteries unrivaled to date. However, with increasing demand and increasingly scarce raw materials such as lithium and cobalt, they are reaching ecological and economic limits.

Battery concepts such as sodium-ion batteries are considered a promising alternative, but have not yet been able to establish themselves due to their lower efficiency and lack of market readiness. However, researchers at the Federal Institute for Materials Research and Testing (BAM) have now succeeded in developing a novel core-shell design for sodium-ion batteries and thus massively increasing performance.

Can sodium-ion batteries achieve a breakthrough?

Sodium is abundantly and inexpensively available as a raw material and therefore offers significant cost advantages compared to lithium. This would also ensure greater security of supply, which would be particularly important for large-scale energy storage and the electrification of the transport sector.

Sodium-ion batteries also offer advantages in terms of safety and resource protection. But so far, the technology has not yet made it out of its niche existence, due, among other things, to its low energy density.

However, researchers at the Federal Institute for Materials Research and Testing could now change that. They have developed a new core-shell design for anodes that significantly increases the performance of sodium-ion batteries.

The researchers have thus solved a crucial problem with this technology. Until now, irreversible losses of storage capacity occurred during the first charging of the batteries.

This is caused by a chemical reaction between the anode and the electrolyte, in which electrolyte molecules decompose on the hard carbon anode. This process allows the molecules to occupy vacancies that are actually intended for storing sodium ions.

Coating prevents storage losses

Previously, this process could only be interrupted once a stable protective film had built up on the anode, protecting it from further decomposition by the electrolyte. But by then, a significant portion of the active material had already lost its performance, which significantly limited the efficiency and lifespan of the battery.

To solve this problem, BAM researchers have developed a novel core-shell design for the anode. “We realized that large storage capacities and efficient film formation in sodium-ion batteries cannot be achieved using a single material,” explains Tim-Patrick Fellinger, BAM energy materials expert. “Because: the better a material is suitable for storage, the more lossy the film formation is.”

For their development, the researchers coated a porous carbon as a storage material in the core of the anode with an extremely thin layer. This then acts like a filter and allows the desired sodium ions to pass through, but keeps the electrolyte molecules out.

In this way, the storage capacity of the anode is preserved so that the battery can deliver constant power even after many charging cycles. The initial efficiency is already at 82 percent – without the new coating, sodium-ion batteries have so far only achieved 18 percent.

The researchers assume that further increases in performance are certainly possible. When it comes to material innovations on the cathode side, science is already close to the theoretical limits. “When it comes to anode materials, however, it is still completely uncertain where these limits lie and which innovative approaches in material development can be used to achieve further progress,” says BAM researcher Paul Appel.

The anode material is now to be further developed in the Berlin Battery Lab, a cooperation between BAM, the Helmholtz Center Berlin and the Humboldt University of Berlin. The research facility specializes in sustainable battery technologies.

Also interesting: