Tesla has apparently made important progress in the production of battery cells. The US company has further developed the dry electrode process and can now produce its 4680 battery at lower costs and with less energy consumption.

Tesla has long been considered the undisputed pioneer of electromobility and a symbol of technological progress. But the company’s image has repeatedly suffered in recent years. Above all, CEO Elon Musk’s public appearance and political positions have meant that Tesla is no longer perceived by everyone as a beacon of hope in the industry.

But with the latest development in battery cell production, Tesla is back as a driver of innovation. According to its own information in the current annual report, the US company has further developed the dry electrode process for its battery production and can now apply this to the anode and cathode.

Has Tesla achieved a breakthrough with the 4680 battery?

Tesla itself announced the technological milestone in its Q4 annual report: “We are now producing dry electrodes for 4680 cells, with both anode and cathode being manufactured in Austin.”

The group now produces its battery cells entirely using the so-called dry electrode process. This is considered particularly demanding and difficult to implement, but it also brings with it numerous advantages. “The production of dry electrodes reduces costs, energy consumption and factory complexity while significantly increasing scalability,” writes Tesla at X.

With the patent that has now been filed, there are many indications that Tesla has overcome one of the central hurdles in modern battery production. Tesla has been using this technology for the anode for several years.

However, there were still difficulties with the cathode, which is why wet coating continued. However, this in turn required energy-intensive drying ovens and the use of toxic solvents, which Tesla can now save through further development.

Dry electrode process is intended for mass production

Tesla also makes it clear in its annual report that the new production method is not a pilot project. The process for the 4680 cells is already in mass production at its battery factory in Austin.

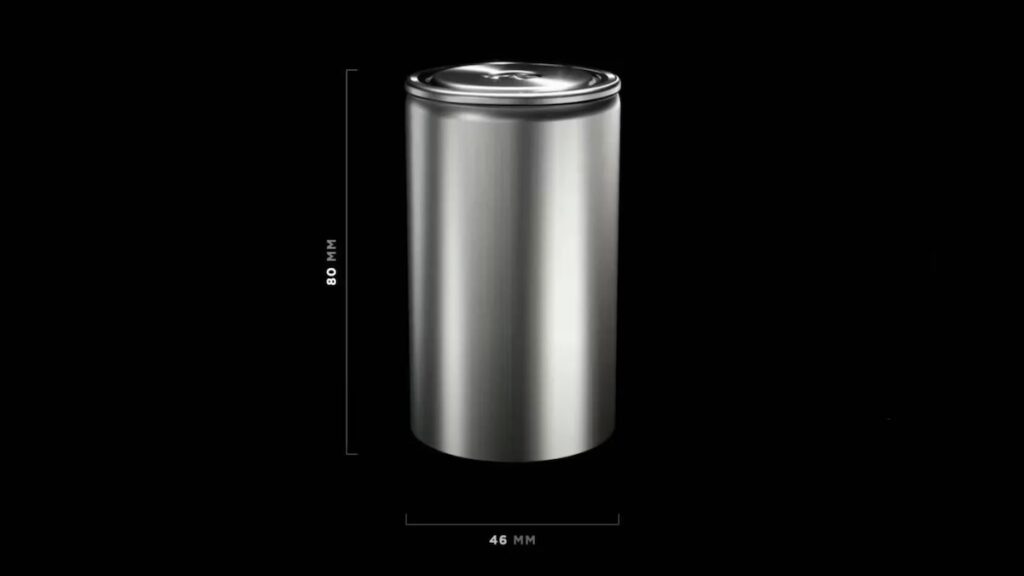

The 4680 cells will also be used again in Tesla’s Model Y in the future. The US company has already used the cells with a diameter of 46 mm and a height of 80 mm here on a trial basis, but they are currently only installed in the Cybertruck.

This is expected to change again in the future, probably also due to the rather subdued sales figures of the Cybertruck. It is not yet known which Model Y models will contain the new cell.

Also interesting: