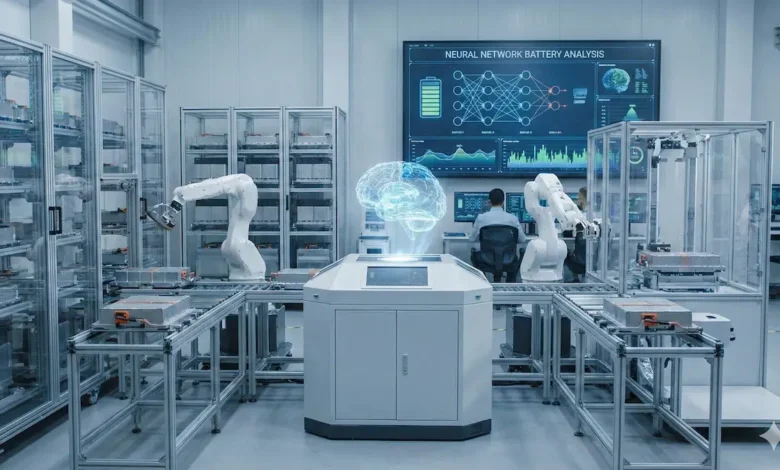

Researchers have developed a method in which AI and machine learning could dramatically reduce the cost and energy required to develop new lithium-ion batteries.

Researchers have developed a new method that the industry could use to produce lithium-ion batteries much faster and cheaper. Machine learning should massively reduce the need for time and energy. The new process solves a problem that has previously made it very slow for experts to predict the lifespan of batteries.

Currently, researchers have to constantly charge and discharge a new battery for months just to test its durability. This laborious testing could use an estimated 130,000 gigawatt hours of electricity by 2040. That’s about half the electricity California generates in an entire year.

AI makes battery development significantly cheaper

Scientists at the University of Michigan have therefore developed a system called “Discovery Learning”. In theory, they shortened the development time by around 98 percent and reduced costs by 95 percent. An AI used data from previous test phases to precisely estimate the entire lifespan of a battery.

The system uses three building blocks so that researchers need less real data for their calculations. First, a learner module specifically selects the prototypes that are most important for accuracy. An interpreter then evaluates the physical properties and historical life data of existing batteries.

This allows the AI to learn from the past to predict the future without having to wait for it. At the end, an Oracle module predicts how long the new batteries will last. The system reports these results directly back to the learner, who then plans the next tests.

Why this is important for our everyday life

This leap can be crucial as we need ever better batteries for electric cars or laptops. The global value of batteries is already $120 billion and is expected to grow to nearly $500 billion by 2030. In this huge market, even small efficiency gains can have a big impact.

Machine learning can speed up development enormously. Still, researchers have yet to prove how well the system works under extremely new designs, fluctuating temperatures or varying electrical loads.

Also interesting: